Holms finmekanik

High quality

Competitive prices

Delivery safety

Competences

Our machine park contains everything from manual machines to CNC-controlled machines that can produce multiple uniformly complex parts for a lot of processes.

We believe that we have some of the best skills in each process area. This is manifested by the fact that the operator is often involved in the dialogue with the customer when we develop new prototypes.

CNC Turning

We offer 2-9 axis CNC turning. We process parts in lengths up to 3000 mm and with diameters from Ø0.1 up to Ø500 mm with tolerances of ±0.002.

More information:

We offer 2-9 axis CNC turning. We process parts in lengths up to 3000 mm and with diameters from Ø0.1 up to Ø500 mm with tolerances of ±0.002.

3-4-5 axis CNC milling

In our milling department we have 18 modern 3-, 4- and 5-axis machining centers on your parts, where several of our machines are equipped with robots. This means that we can run our cutters 24 hours a day. The item size is from 0.1 grams to 50 kg. X-Y-Z max is 1600x900x1000 mm.

More information:

In our milling department we have 18 modern 3-, 4- and 5-axis machining centers on your parts, where several of our machines are equipped with robots. This means that we can run our cutters 24 hours a day. The item size is from 0.1 grams to 50 kg. X-Y-Z max is 1600x900x1000 mm.

Bending and assembling

In our assembly department we offer small and larger assembly tasks of, among other things. equipment and other precision tasks. In addition, we can offer soldering, bonding, epoxy casting and finer mounting tasks under the microscope with very sharp tolerances. Measurement/testing of electrical components with documentation is carried out, as well as pressure testing.

More information:

In our assembly department we offer small and larger assembly tasks of, among other things. equipment and other precision tasks. In addition, we can offer soldering, bonding, epoxy casting and finer mounting tasks under the microscope with very sharp tolerances. Measurement/testing of electrical components with documentation is carried out, as well as pressure testing.

Surface treatment

We offer all coatings, e.g. anodization, chromital, zinc plating, nickel, chromium and electric polishing.

More information:

We offer all coatings, e.g. anodization, chromital, zinc plating, nickel, chromium and electric polishing.

Production and prototype wire friction

We offer wire rubbing and 5-axis wire rubbing up to 400mmx500mm.

More information:

We offer wire rubbing and 5-axis wire rubbing up to 400mmx500mm.

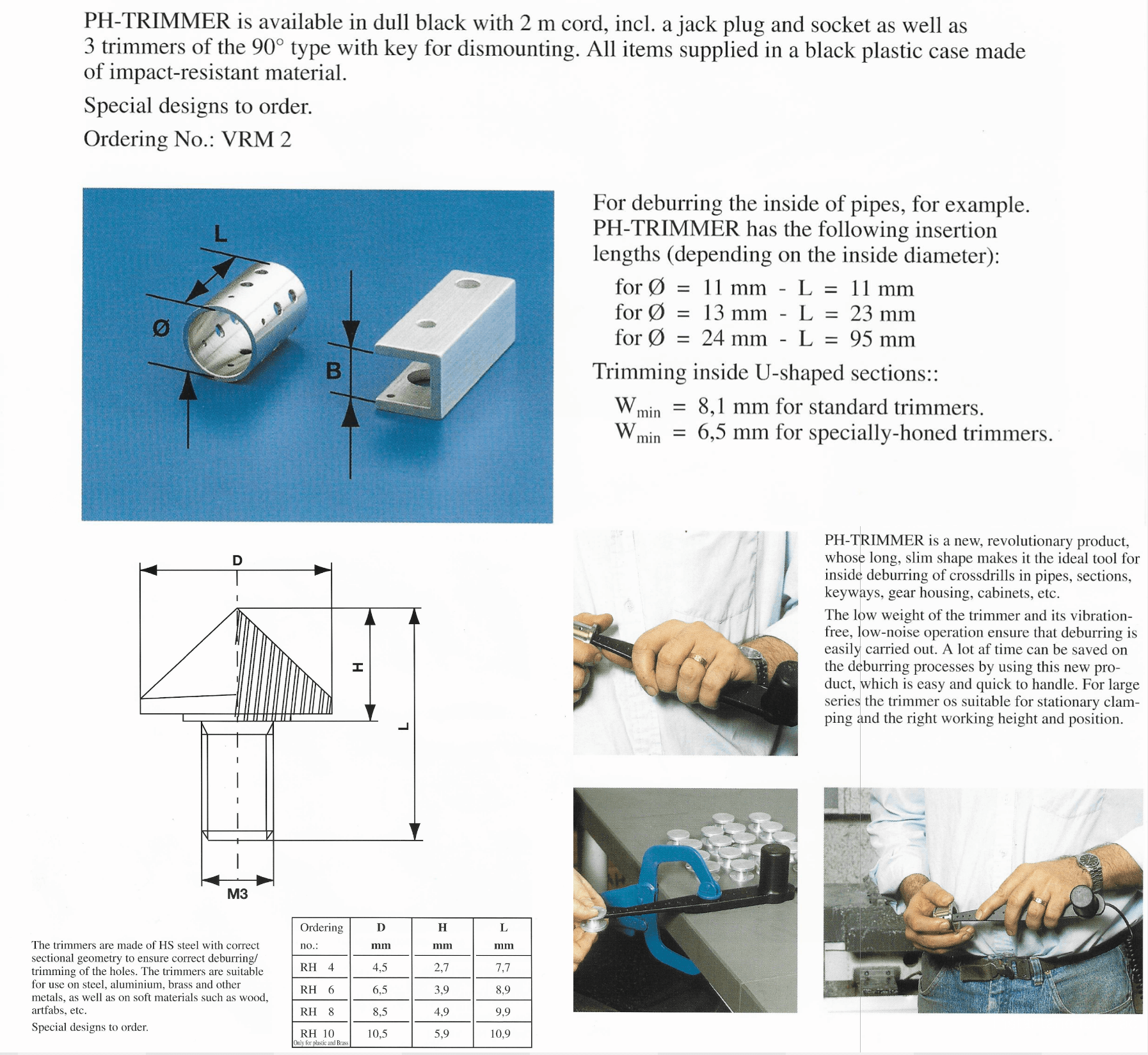

Deburring

We offer drum vibration and electro chemical deburring.

More information:

We offer drum vibration and electro chemical deburring.

Grinding, patching, honing and superfinish

Grinding (flat, internal and external round grinding, and centerless grinding) Subject size Ø450 x 1500 mm.

Capability honing: Up to Ø 60 mm internal and outer diameter.

Capability superfinish: Roughness < Ra 0.02 μm

More information:

Grinding (flat, internal and external round grinding, and centerless grinding) Subject size Ø450 x 1500 mm.

Capability honing: Up to Ø 60 mm internal and outer diameter.

Capability superfinish: Roughness < Ra 0.02 μm

Hardening

We assist with all types of curing and insertion such as:

- Expanite

- gas nitride

- carbon nitride

- tenifer

- vacuum hardening

- voltage glow

- Normalization

More information:

We assist with all types of curing and insertion such as:

- Expanite

- gas nitride

- carbon nitride

- tenifer

- vacuum hardening

- voltage glow

- Normalization

Measurement, documentation and quality control

In recent years, we have invested heavily in measuring machines and measuring tools, which means that we probably have the most advanced measuring room you can find from a partner.

We have at our disposal

- 3D coordinate measuring machines with motorized Renishaw measuring head and automatic tool changer

- Surfasan safety and roughness meter, interference measurement equipment for plane unit measurement

- Mahr longitudinal measuring machine

- Taylor Hobson Talyround roundness measuring machine

- Laser measuring machines

- Digital Altimeter

- Hardness meter

- Profile projector

- Nikon measuring microscopes

- Mercer air metering app species

Laser engraving

All types of parts.

Name, logo, markings, etc.

More information:

Holms Finmekanik has extensive experience in working closely with the customer's R&D/development department on subject development, optimization, component reduction, assembly production, etc.

3D and optical measurement

Measuring parts are produced on our 3D measuring machines and via our latest optical measuring machines.

More information:

Measuring parts are produced on our 3D measuring machines and via our latest optical measuring machines.

Soldering and welding

We offer both hard and soft welding, Mig/Tig welding, laser welding and laser engraving.

More information:

We offer both hard and soft welding, Mig/Tig welding, laser welding and laser engraving.

Construction, development and testing

We offer pressure tests from 300-800 bars.

More information:

We offer both hard and soft welding, Mig/Tig welding, laser welding and laser engraving.

Gear milling

We offer the pretanding of items in dimensions Ø6-Ø300.

More information:

We offer the pretanding of items in dimensions Ø6-Ø300.

Materials

We are working with a wide range of different materials, including:

Stainless materials

Acid-resistant • Titanium stabilized acid-resistant • Automat grades • Sandvik 2002 • Hastelloy • Inconel 625 • Monel • Stainless steel needles

Steel alloys

All steel alloys • Hardened steel alloys

Metals

Brass • Copper • Bronze alloys • All aluminium alloys

Plastic

POM • PVC • PEEK • PETP • PP • PMMA • Nylon • PTFE • PEHD • LEXAN

Specialions

Titan Grade 2 • Titan Grade 3 • Titan Grade 4 • Titan Grade 5 • Tungsten • Hard Metal

Other materials

Ceramics

Prototyping

We are constantly working to develop our skills, both at “Holms Finmekanik” and “Holms Machinery Asia”

At our factory in Thailand (HMA) we are manufacturing prototypes within 1-2 weeks, depending on the scope.

Product design

We are glad to participate early in the development work together with our engineers. This is done partly to ensure “Design for manufacturing” and to ensure that our customers do not have unknown parameters in terms of price, tool costs and items that are not production suitable. Today, the production of prototypes represents about 30% of our turnover.

Services for the production of prototypes

- 3-4 and 5 axis CNC milling

- 7-axis CNC turning

- Hole rubbing from 0.3-3mm with full CNC control

- Wire rubbing with full CNC control

- SolidWorks and machining via Edgecam

- Assembly and testing